Overview

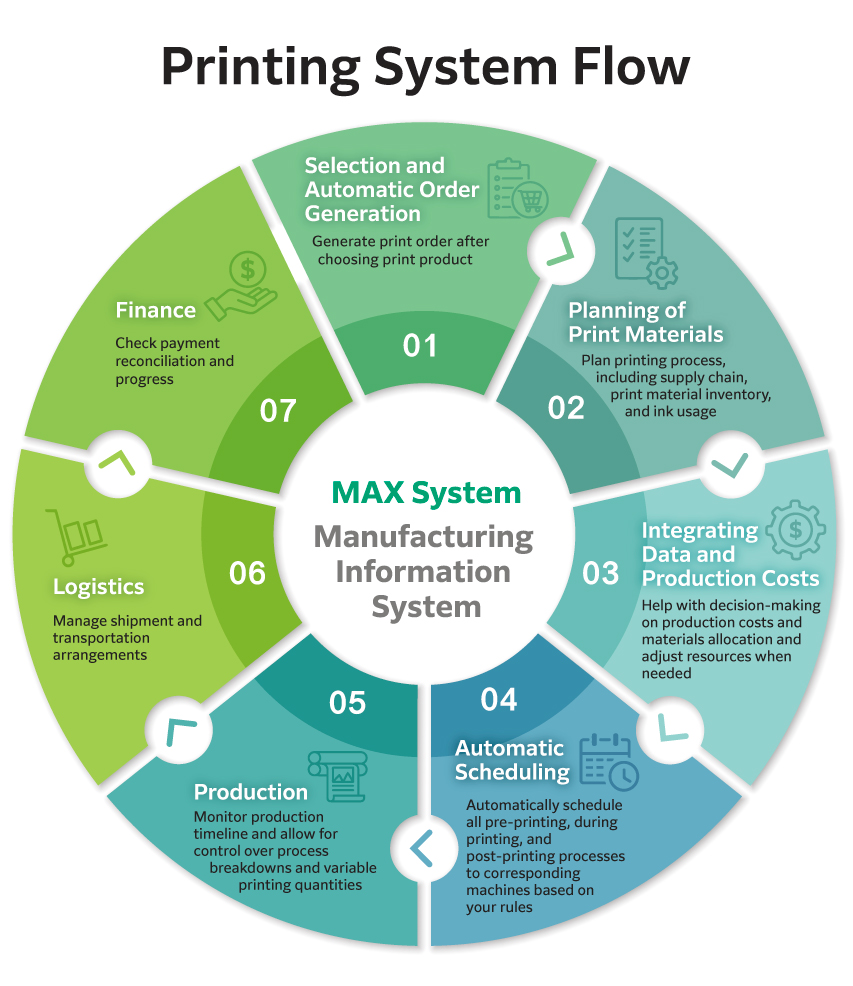

Facing a large volume of diverse print orders, printing factories require manpower to plan the printing process, verify and monitor it. This can inevitably lead to a lack of flexibility, increased production costs and lead time. Using digital technologies, such as the MAX System - a transformative manufacturing information system, printing processes can be automated and streamlined.

Using data and analytics, the system ensures precise planning of the printing process, material inventory management, allocation of human resources and even logistics management, thereby improving operational efficiency.

Challenge

Shortage of manpower management When dealing with a large volume of orders, there is a shortage of manpower to handle the manual and complex procedures simultaneously, which leads to mistakes and omissions, and hence a delay in delivery time. |

Time-consuming prepress process After receiving an order, it is time-consuming to verify material inventory, paper procurement, and calculation of production costs, which slows down decision-making. |

Lack of flexibility Any changes to an order will require a complete re-planning of all processes manually, undermining the flexibility of business operations. |

Solution

Designed for the printing industry, MAX System Manufacturing Information System assists you in managing the entire production process, such as order enquiries, preliminary resource allocation, production costs, scheduling, production progress, logistics, and finance. All of these processes can be efficiently controlled through a unified platform. Key advantages include the ability to handle a large volume of print orders, increased production efficiency, saved manpower and time, enhanced business operations, and scalability for business expansion.

Advantage

| |

Simplifying Processes for Enhanced Efficiency After order approval, the system automatically secures the required materials, reducing the need for documentation or approvals in the material allocation process. This significantly saved manpower and time, enhancing efficiency. |

Calculating Ink Usage to Ensure Smooth and Green Production By calculating the quantity of specialty and regular color inks required before printing, it prevents disruptions in production schedules due to ink replenishment and reduces wastage at the same time. |

|

| |

Analyzing Production Costs for Profit Maximization Upon completion of production, the system automatically gathers production and material costs, and combines them with other expenses from logistics and management. It automates the integration of the actual costs for each order to facilitate further analysis. |

|

Enhancing Production Transparency With a unified dashboard, everyone can see the progress of production, paper, and other supplementary materials for all orders, which improves inter-departmental transparency and communications. |

Realizing an Integrated Digital Printing Process with FUJIFILM BI HK Production Digital Printing System

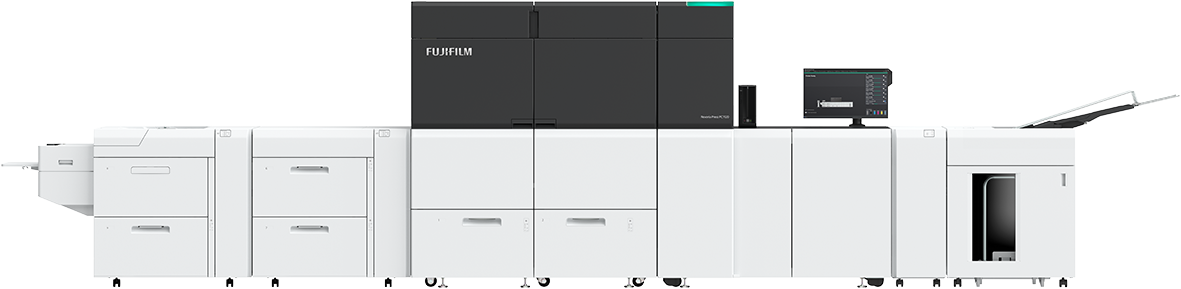

FUJIFILM BI HK’s flagship production digital color printing system, Revoria PressTM PC1120, is a groundbreaking six-color printing engine that provides exceptional color combinations. With up to two special toners for selection, including Gold, Silver, Transparent, White and Neon Pink, in addition to the basic CMYK toners, it opens up numerous possibilities for your printing output. Equipped with AI-driven image processing capabilities, it also facilitates easy proofing and correction of images for the production of prints and completion of complicated processes.

Brochure

You may download the PDF here

MAX System Brochure-TCProduct Enquiry

Max System Manufacturing Information System

To learn more about the MAX System Printing Business Management System, please fill out the registration form. We will contact you as soon as possible.