Overview

- Superior productivity with high-speed printing of 120 ppm even when printing in 6 colours.

- High-definition expression with high-output resolution at 2,400 x 2,400 dpi.

- High-performance print server that maximises print engine productivity.

- Supports a broad range of stocks: 52 gsm lightweight paper, 400 gsm heavyweight paper, minimum 98 x 148 mm and up to 330 x 1,200 mm.

- Various feeding and finishing options to streamline workflow from print to post-press.

Features

Achieves both image quality and productivity at a high level.

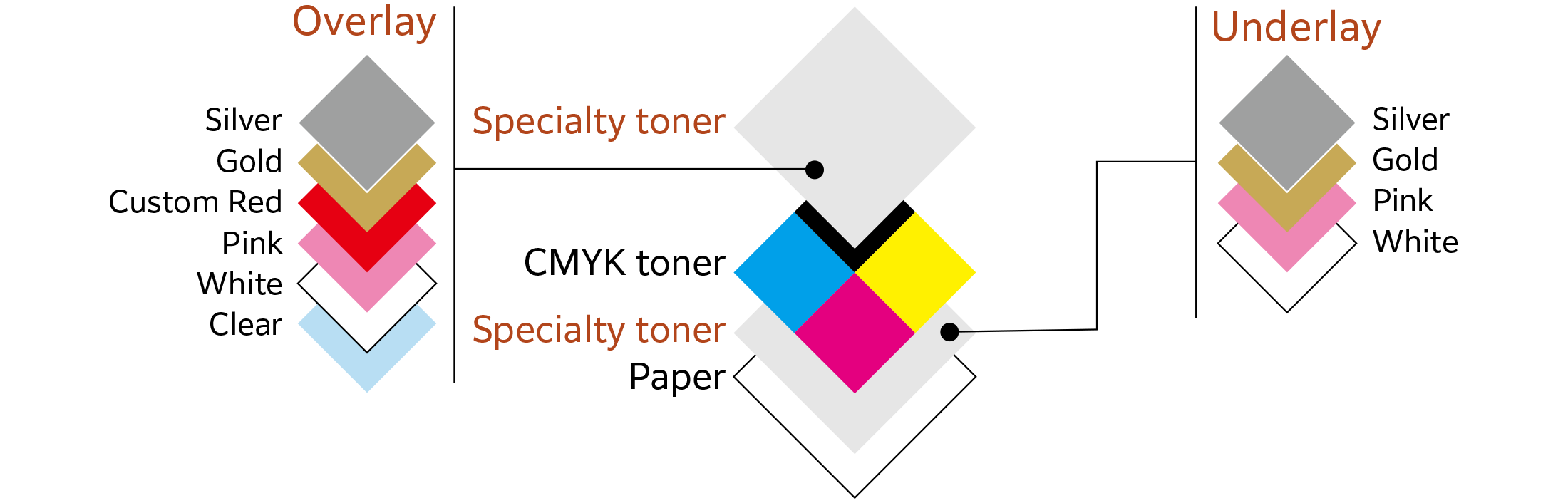

1 pass 6-colour print engine

In addition to CMYK toner, the press can load a maximum of two specialty toner stations. For specialty toner, choices of Clear*1, Gold, Silver, White, Pink and Custom Red*1*2 toners are available. By overlaying CMYK on Silver or Gold, you can print various brilliant metallic colours. The rich colour expressions created by the 6-colour print engine can expand your business.

- *1: Clear and Custom Red toner can only be used for Overlay.

- *2: Custom Red toner is available in limited countries.

- Note: Users can swap the colours of the specialty toner unit faster and more easily than an offset press.

You can create a variety of metallic effects with Gold and Silver underlay.

PANTONE® and our unique pre-installed metallic colours are available.

Pink toner can create eye catching design with fluorescent pink.

Pink toner can make the colour gamut expand. More vivid colours can be reproduced.

- Note: Pink toner can be used to reproduce the vivid colors of red, orange, and purple in RGB.

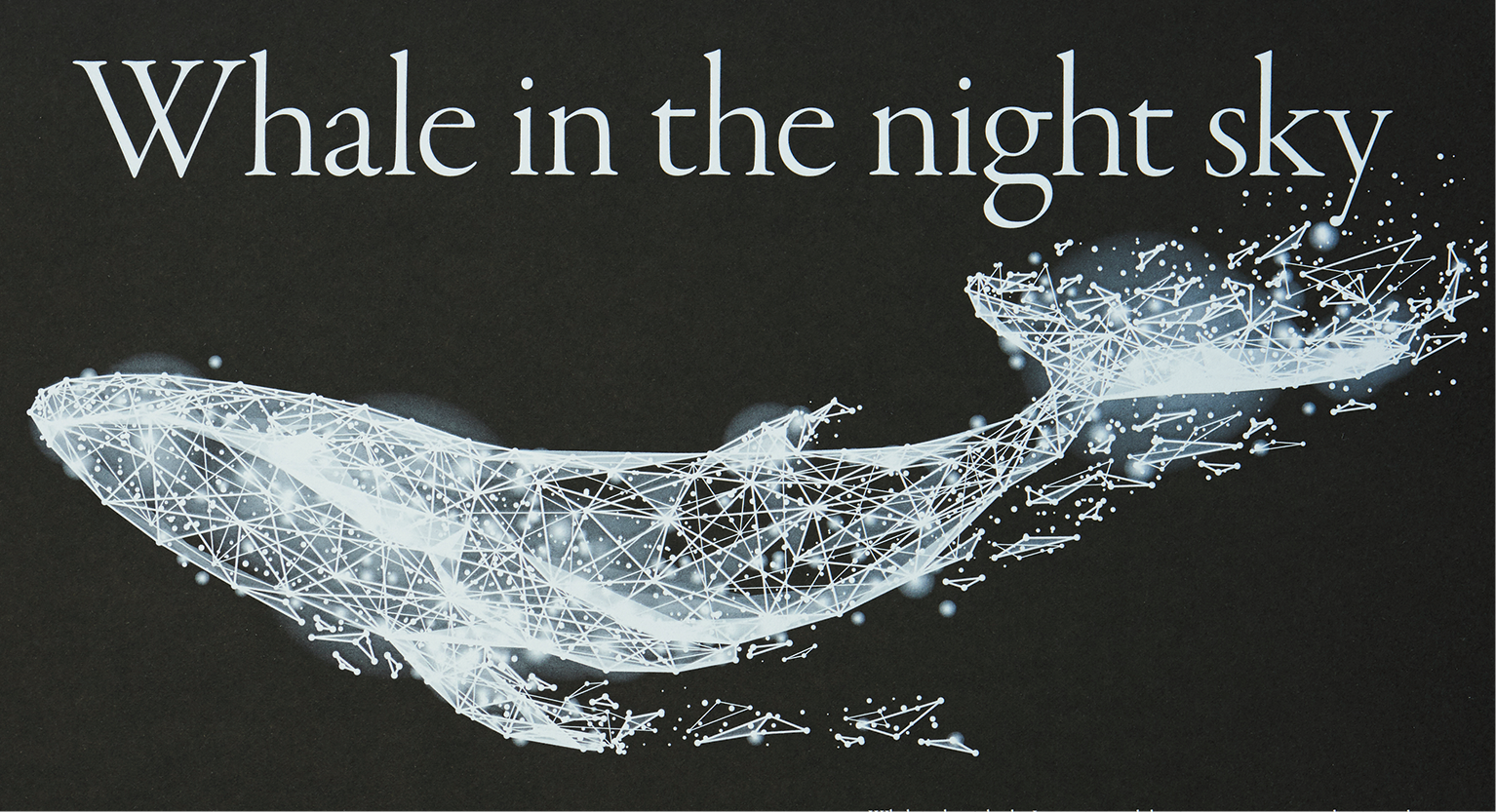

You can print on coloured media with high opacity White toner.

White underlay printing can be used as a base for coloured paper and transparency films.

Clear and metallic colours are less prone to be duplicated and effective on tickets, etc.

You can create premium print effects with Silver and Gold toners.

High resolution printing of 2,400 x 2,400 dpi

The heart of the printer, ROS*1, uses VCSEL*2 as a light source. It enables printing at 2,400 x 2,400 dpi high resolution by drawing images simultaneously with multiple laser beams.

- *1: Raster Output Scanner

- *2: Vertical Cavity Surface Emitting Laser

Super EA*-Eco toner for high image quality

Super EA-Eco toner with extremely small particle size allows smooth reproduction of gradations in photographs, uniform density and sharper fine lines and text. It also produces easy-to-read printed text with less glare.

- * EA: Emulsion Aggregation

Easy and quick adjustment

The inline sensor is built into the printer body, allowing easy and quick calibration. It also has an automatic adjustment function that allows you to adjust* multiple settings at once. It minimises the effort required for maintenance and downtime.

- * Batch adjustment of the following can be performed: Auto Alignment, 2nd Bias Transfer Roll Correction, Auto Tone Correction, Density Uniformity Correction.

Print server with high resolution and fast processing.

Image data processing maximising print engine performance

High quality image data can be generated with RIP processing of 1,200 x 1,200 dpi and 10 bit (1,024 gradation levels) on the print server. In addition, high resolution and smooth screen image of 2,400 x 2,400 dpi can be generated on the device with our unique HQ digital screen technology (MACS*) employed. These data processing technologies can generate high image quality brought from the maximisation of the print engine performance.

- * Micro Accurate Control Screen.

Professional colour management system

Supports various CMYK colour standards such as Fogra, SWOP and GRACoL.

Calibration for G7® standard

G7® calibration achieves consistent gray balance and neutral tonality across different printing processes, substrates, and printing conditions.

- Note: A standard that is widely adopted in the printing industry to ensure color consistency and quality across various printing technologies and platforms.

Image Enhancement in a more beautiful way

Higher image quality has been implemented with "Edge Enhancement" that fixes jaggedness on the edge of thin line and text outline and "Adjust Invert Text/Line Weight" that fixes thickened / blurred text.

- Note: Default setting: OFF

Selecting different screens for individual objects for optimum image quality

You can select the suitable screen for each object such as a text and photo. The FM screen is effective for moire. Granular roughness that tends to occur on FM screens is suppressed by the dot arrangement suitable for the electrophotography profile, realising a smooth image quality.

Make skin texture beautiful

Equipped with a function to brighten the image using fluorescent Pink toner. By separating into CMYK + Pink, skin tones can be brighter, and the texture of the skin can be reproduced smoothly and beautifully.

- Note: You can choose 3 levels of effect. Since the pink layer is generated from magenta, it affects the images containing magenta.

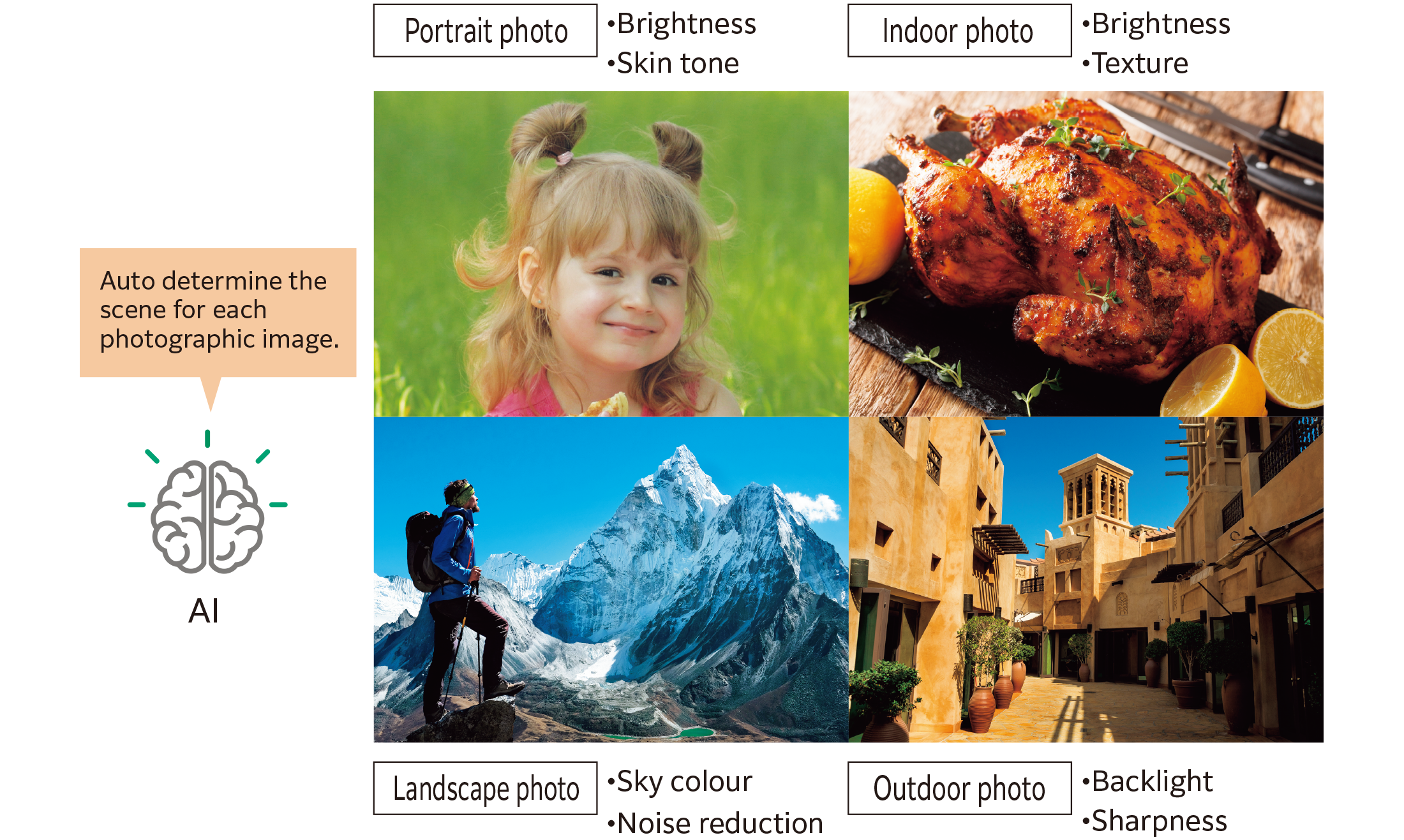

AI-based photo quality optimisation*

AI (Artificial Intelligence) automatically determines the scene for each photographic image on the page and corrects the image appropriately for each of them. Low quality images, such as poor contrast and brightness, can be automatically corrected.

- * Applies to RGB type images.

A wider range of media types and finishes.

Supporting a wide range of paper weights from lightweight paper of 52 gsm to heavyweight paper of 400 gsm

Paper sizes ranging from A6 to 330 x 488 mm are available. Full-bleed printing on SRA3 (320 x 450 mm) is also possible and it is useful to create brochures or leaflets that need to have bleed.

Supports banner sheets of maximum 1,200 mm

You can print up to 330 x 1,200 mm banner sheets for simplex printing*. Widen the scope of new printing application such as powerful panoramic posters.

- Note: Please contact our sales representative for paper feeder or output module that is required for Banner sheet printing

- * Up to 330 x 729 mm for automatic duplex printing.

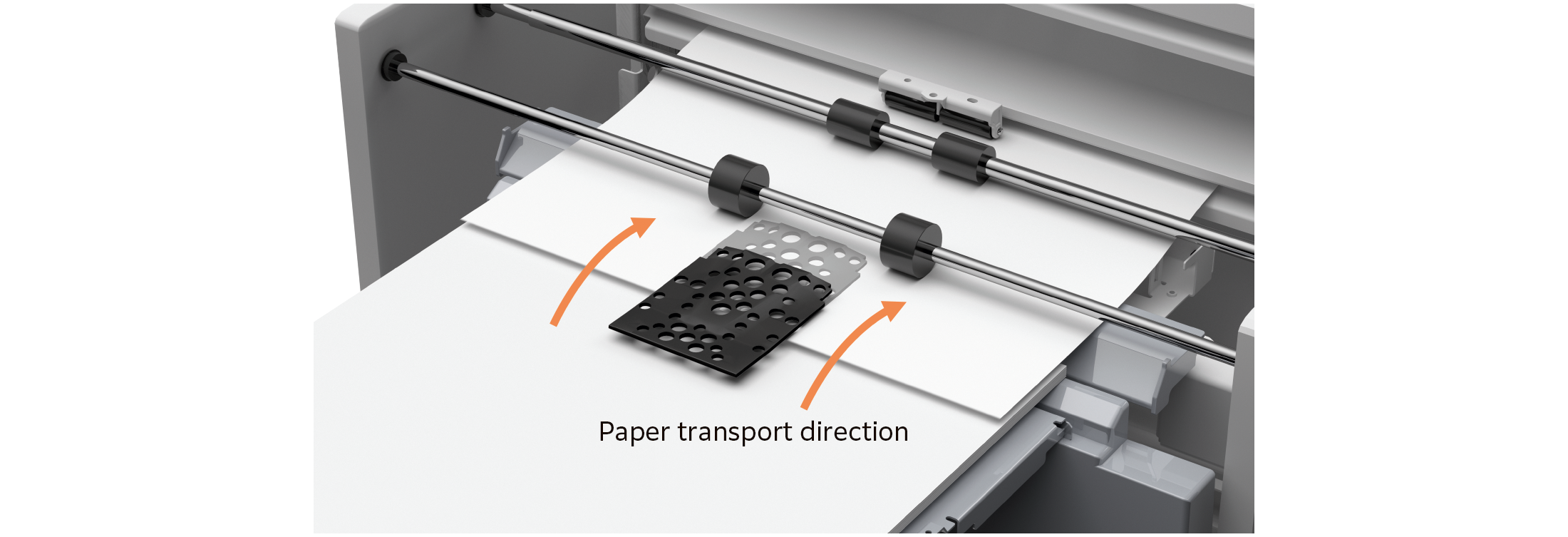

Eliminate static electricity on Film and Metallic media

Film and metallic media are easily charged by static electricity when printing, and the printed media may stick together. However, the inline static eliminator module* makes it easy to stack and align these media.

- * Optional "Static Eliminator D1".

Various inline finishing*

You can create a variety of finished products with full bleed, trimming, crease and folding options.

- * Optional

Connection with third-party finishers*

Third-party finishers* can be connected inline.

- * Optional "High Capacity Stacker A1 with Transport Module" is required.

Please contact our sales representative for third-party finishers.

"Air Suction Feeder*" with enhanced paper handling capabilities

Using air suction shuttle head picks up each sheet individually and delivers it securely. This improves paper feeding performance for low quality, textured and coated media.

- * Optional

Inspection with Automatic Recovery

It automatically checks printing defects. The error sheet can be discharged and automatically reprinted. It saves you a lot of time and effort.

Image Inspection: Detects printing defects such as dots, stains, pinholes, streaks, dog ears by comparing scanned images with RIP images in real time.

Barcode/OCR Inspection: Verifies the printed barcordes or OCR fonts are readable, the numbers are sequential or the numbers on side 1 and side 2 are match.

Stability: You can control print quality by knowing the alerts of density fluctuations or misalignment during printing.

- Note: Options are required.

Please contact our sales representative for details.

Inspects printed barcode (example)

Inspects printed barcode (example)

Expand applications with combined options.

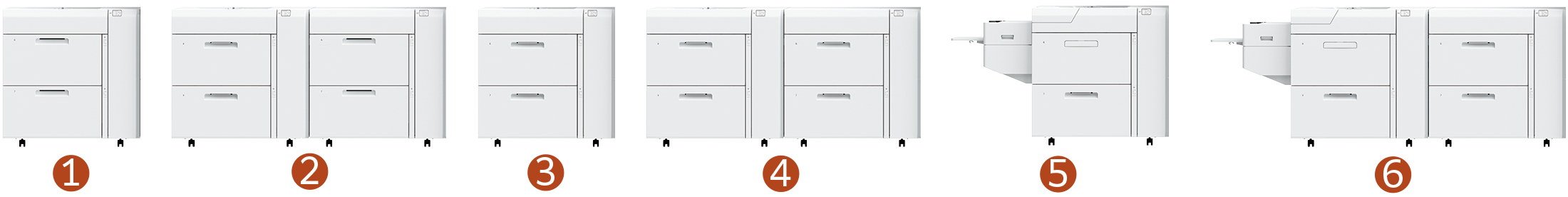

Feeding options

- 1. High Capacity Feeder C3-DS + Multi Sheet Inserter*1

-

- Air assist

- Multifeed detection

- 2,000 sheets x 2 trays+250 sheets

- Maximum SRA3, 330 x 488 mm - 2. 2nd High Capacity Feeder C1-DS+ High Capacity Feeder C3-DS + Multi Sheet Inserter*1

-

- Air assist

- Multifeed detection

- 2,000 sheets x 4 trays +250 sheets

- Maximum SRA3, 330 x 488 mm - 3. Air Suction Feeder C1-DS*2

-

- Air suction

- Multifeed detection

- 2,100 sheets x 2 trays+250 sheets

- Maximum SRA3, 330 x 488 mm - 4. Chained Air Suction Feeder C1-DS-L*2 + Chained Air Suction Feeder C1-DS-R

-

- Air suction

- Multifeed detection

- 2,100 sheets x 4 trays + 250 sheets

- Maximum SRA3, 330 x 488 mm - 5. Air Suction Feeder C1-DSXL*2 + Banner Unit for Air Suction Feeder C1-DSXL

-

- Air suction

- Multifeed detection

- Long sheets feeding

- 800 sheets + 2,100 sheets+250 sheets

- Maximum 330 x 1,200 mm (Upper tray) - 6. Chained Air Suction Feeder C1-DSXL-L*2 + Chained Air Suction Feeder C1-DS-R + Banner Unit for Air Suction Feeder C1-DSXL

-

- Air suction

- Multifeed detection

- Long sheets feeding

- 800 sheets + 2,100 sheets x 3 trays+250 sheets

- Maximum 330 x 1,200 mm (Upper tray)

Output options

Full Configuration: W 10,462 x D 1,104 x H 1,786 mm

Full Configuration: W 10,462 x D 1,104 x H 1,786 mm

- 1. Interface Decurler Module D1

- - Real-time paper curl correction

- 2. Inserter D1

- - Cover / sheet insertion

- 3. Static Eliminator D1

- - Eliminate static electricity

- 4. Smart Monitoring Gate D1

- - Print inspection

- 5. High Capacity Stacker A1

-

- 5,000-sheet offset-stacking

- Single and dual combinations

- Stacker cart

- Long sheets Output - High Capacity Stacker A1 with Transport Module

-

- Connection with 3rd party finisher

- 5,000-sheet offset-stacking

- Stacker cart

- Long sheets Output - 6. Crease/Two-sided Trimmer D2

-

- Two-sided trim

- Crease - 7. Folder Unit CD2

-

- Z fold half sheet

- Tri-fold - 8. Finisher D6

-

- Sort / Stack

- Stapling

- Hole punch*3

- Long sheets Output - Finisher D6 with Booklet Maker

-

- Sort / Stack

- Stapling

- Hole punch*3

- Single fold

- Saddle staple

- Long sheets Output - 9. Square Back Fold Trimmer D1

-

- Face trim

- Square back

- Offset Catch Tray

-

- Offset Stack

- Long Catch Tray

-

- Long sheets Stacking

- *1: Multi Sheet Inserter or Multi Sheet Inserter for Banner Print is required.

- *2: Multi Sheet Inserter for Banner Print is equipped as standard.

- *3: Optional

Infinite colours. Ultimate productivity.

The Fiery PC11 for the FUJIFILM Business Innovation Revoria PressTM PC1120 includes intelligent automation and built-in tools to deliver unique, differentiating prints.

Unrivaled productivity

The Fiery server features HyperRIPTM, the innovative Fiery feature that processes large and complex jobs at faster speed, which allows you to take on new, higher-value opportunities with confidence. Increase efficiency with the automation benefits from the included, browser-based Fiery JobFlowTM Base software.

Built-in print intelligence

Reduce setup time and cut waste with Fiery JobExpertTM - a built-in feature in Fiery Command WorkStation® -that automatically analyses incoming PDF files and dynamically chooses optimal Fiery print settings.

A unified, integrated print room

Manage all your Fiery DrivenTM cutsheet and wide format printers from Fiery Command WorkStation to centralise job management. Integrate your print production workflow with management information systems, Web-to-Print systems, and popular prepress workflows for end-to-end automation.

Use the Fiery Workflow Suite of integrated products, like the included Fiery Impose-Compose, or Fiery JobMaster, to accelerate makeready from job setup through production in one single, visual interface.

Differentiate with personalisation

Fiery FreeFormTM Create, an included application, allows you to quickly and simply create personalised jobs for print production. Add variable elements such as text, images, or barcodes with just a few clicks. You can even create personalised files that include specialty colours for extra visual impact.

Dazzle with specialty colours

Add premium print effects by utilising up to two specialty colours simultaneously to create brilliant metallics and infinite other rich colour expressions. Built-in tools like Fiery ImageViewer and Fiery Spot Pro make working with specialty colours easy. And the integrated Fiery Smart Estimator allows you to estimate your specialty colour usage before printing a single page.

Fiery® PC11 specifications

Fiery DrivenTM engines

- Revoria PressTM PC1120

- Supports all engine finishing devices

Hardware and platform

- Dual Intel® Xeon® 12-Cores

- 32 GB RAM

- SSD boot drive for OS & Fiery software

- 2 x 2 TB HDD

- Fiery NX Station GL

- USB 3.0: 4 rear ports, 3 on Fiery QuickTouchTM panel, 2 on NX Station GL

- Calibration: Inline sensor or EFITM ES-3000 spectrophotometer

- Fiery FS400 Pro system software

- Microsoft Windows® 10 IoT Enterprise 2019 LTSC

- Fiery Installer Builder

Productivity and workflow

- Fiery Command WorkStation®

- Fiery JobExpertTM

- Fiery HyperRIP

- Fiery JobFlowTM Base

- Fiery Smart Estimator

- Fiery Impose-Compose

- Fiery Hot Folders/Virtual Printers

- Fiery drivers for Linux, Windows and Mac®

- Fiery WebToolsTM

- Fiery server presets

- Fiery Go (AndroidTM and iOS)

- Fiery Paper Catalog

- Spool-RIP-Print simultaneously

- Booklet Maker

- Pad printing

- Copy numbering

- Rush Printing, Schedule Print, Suspend on Mismatch, Job Reorder, Proof Print, and Quick Doc Merge

- Set Page Device Mapping

- Sample Print

- Pad printing

- Auto trapping

- Mixed Subset Finishing

- Strict ordered printing

- Slip sheet, job cover page and offset by sheets, copies or sets

- Fiery Custom Crease

- EFI IQ: Dashboard, Insight, Notify, Go

Colour and imaging

- Fiery EdgeTM colour profiles

- Specialty colour features

- Supports all engine specialty toners

- Fiery Spot Pro enables creation of dazzling custom spot colours

- Multi-Pass Printing of CMYK and/or specialty colours for tactile, dimensional effects

- Invert specialty colour

- Double print specialty colour

- PANTONE® Color Enabled

- Object Oriented Halftones

- RGB and CMYK rendering intent control

- Fiery Ultra Smooth Gradients (1,200 x 1,200 dpi, 10-bit rendering resolution)

- Text and graphics enhancement: Fiery Dynamic HD Text and Graphics, reverse text and graphics growth, colour text and graphics enhancement, trailing edge compensation, colour character edge enhancement, black text and graphics anti-aliasing, text/graphics sharpness

- Fiery Graphic Arts Pro Package*1

- Fiery Spot Pro, Fiery ImageViewer, Fiery Preflight, Fiery Postflight, Fiery Control Bar Builder

- Composite overprint

- Image smoothing

- Image enhance

- Fiery Image Enhance Visual Editor

- Fiery Color Profiler Suite

Variable data printing

- Fiery FreeFormTM Create

- Supported file formats:

- Fiery FreeForm Plus, PPML v2.x/3.0, PDF/VT 1 and 2, Creo VPS

- VDP Record and Set Level Finishing, VDP Record Range Printing, Define Record Length, VDP Resource Manager, VDP Raster Preview, VDP imposition

Adobe interpreter support

- Adobe® PDF Print Engine® 5.3*2

- CPSI version 3020

File format support

- Adobe® PostScript® Levels 1, 2, 3; Adobe PDF; PDF/X-1a, 3, and 4; EPS; JPEG; TIFF

- Microsoft Office document formats: doc, docx, xls, xlsx, ppt, pptx, pub (via Hot Folders)

Security

- Secure Erase

- Security profiles

- FIPS 140-2 compliant data encryption

- ISO/IEC 15408 & IEEE Std 2600 (Common Criteria) compliant*3

- Port-based access controls

- 802.1x advanced authentication methods

- USB security

- Port blocking

- IP filtering

- IPsec network encryption

- Secure connections using HTTPs with support for TLS 1.3

- Secure Printing

- Digitally signed software updates

- Windows 10 OS security features

- Authentication/Accounting

Networking/Connectivity

- TCP/IP, AppleTalk, Bonjour support, SNMP, Port 9100, IPP, FTP, SMB, WSD, point and print, print via email (PS/PDF), IPv6 support, LDAP authentication

EMC

- FCC Title 47, Part 15 Subpart B.

- ISED of Canada, ICES-003.

- EN55032: 2015 +A11: 2020

- EN 55035: 2017/A11: 2020

- AS/NZS CISPR 32: 2013.

- CCC-China

- KC-Korea

- BSMI-Taiwan

Safety

- CB Scheme-IEC-62368-1, 2nd Edition

- EN 62368-1, 2nd Edition,

- CE Mark (EU)

- cTUVus -NA

- CCC-China

- BSMI-Taiwan

Integration

- JDF v1.7

- Fiery API

- MIS and Web-to-Print integration ready

- Prepress workflow integration (Agfa® Apogee, Kodak® PRINERGY, Heidelberg® Prinect, SCREEN EQUIOS)

Optional Fiery software and hardware

- Fiery Dual Specialty Toner Package License

- Fiery IPDS

- Fiery JobMasterTM*4

- Available as a 5-year term license

- Adobe® Acrobat® Pro 2020 Kit

- EFI ColorGuard*4

- Fiery disk drive security kits

- EFI ES-6000 spectrophotometer

Power

- Print server

- Auto-switching: 100-240 VAC

- 50/60 Hz, 6 Amps @100 VAC, 5 Amps @240 VAC

- Maximum power usage: 600 W

- Typical power usage: 200 W

- NX Station GL

- Auto-switching: 100-240 VAC

- 50/60 Hz, 1.2 Amps

Dimensions/Weight

- Print server

- Height: 20.75" (527.05 mm)

- Width: 9.25" (234.95 mm)

- Depth: 22.5" (463.55 mm)

- Weight: 48 lbs (21.77 kg)

- NX Station GL (without server)

- Height: 60" (1,525 mm)

- Width: 31.5" (800 mm)

- Depth: 34.9" (866 mm)

- Weight: 92.5 lbs (41.9 kg)

- *1: Includes 5-year term license

- *2: Updated with enhancements and service releases on an ongoing basis

- *3: With proper configuration by end customer or service provider

- *4: Free 30-day trial available

Specifications

Functions-and-Specifications

- File Size:

- 331.69 KB

- Document Type:

- Portable Document Format

You may download the PDF here

Functions-and-SpecificationsYou may download the PDF here

Fiery PC11 LeafletBrochure

Revoria Press PC1120 Brochure

- File Size:

- 982.94 KB

- Document Type:

- Portable Document Format

You may download the PDF here

Revoria Press PC1120 BrochureHow To Buy

Revoria Press PC1120

We make it easy for you to purchase products, supplies and services from us. Our extensive network of representatives can help you choose the right solutions for your business needs.