The Mini 4300 Head Mount is designed to provide an integration solution between the printbar and a transport system, while providing 5 axes of adjustment for high image quality results.

- Material

Stainless steel, aluminum

- Weight

Approximately 11 kg [25 lbs.]

- Mounting holes

M8 x 1.25 thread, 25.4 x 25.4 square hole pattern

- Yaw adjustment

± 3 degrees

- Roll adjustment

± 2.5 degrees

- Pitch adjustment

± 2 degrees

- Standoff adjustment

19 mm [0.75 in.]

- Horizontal coarse adjustment

320 mm [12.6 in.] max

- Horizontal fine adjustment

9 mm [ 0.35 in.]

The LED lamp is used for UV/LED curable inks. Results may vary.

- Size

77 x 90 x 231.3 mm [3 x 3.5 x 9 in.]

- Weight

1.82 kg [2.2 lbs.]

- Standoff distance

2 mm [0.08 in.]

- Noise

54dbA @ 1 m [3.3 ft.]

- Max operating temp

35°C [ 95°F]

- Input power

120V

- Input signal

Analogue or RS485

The Aqueous dryer is used for aqueous inks, organic solvents and latex. Results may vary.

- Lamp size

362/508 x 22/67 x 237 mm [14.2/20 x 0.9/2.6 x 9.3 in.]

- Drying width

44 mm [1.7 in.]

- Lamp weight

1.7 kg [3.7 lbs.]

- Lamp power

Up to 3.1kW emitter

- PSU input power

230VAC, 14A, 50/60 Hz*

- PSU weight

2 kg [4.4 lbs.]

- PSU size

128 x 250 x 60 mm [5 x 9.8 x 2.4 in.]

- Mount height adjustment

60 mm [2.4 in.]

- Mount flip-up angle

45° and 90°

- Mounting holes

M8, 100 mm [3.9 in.] width

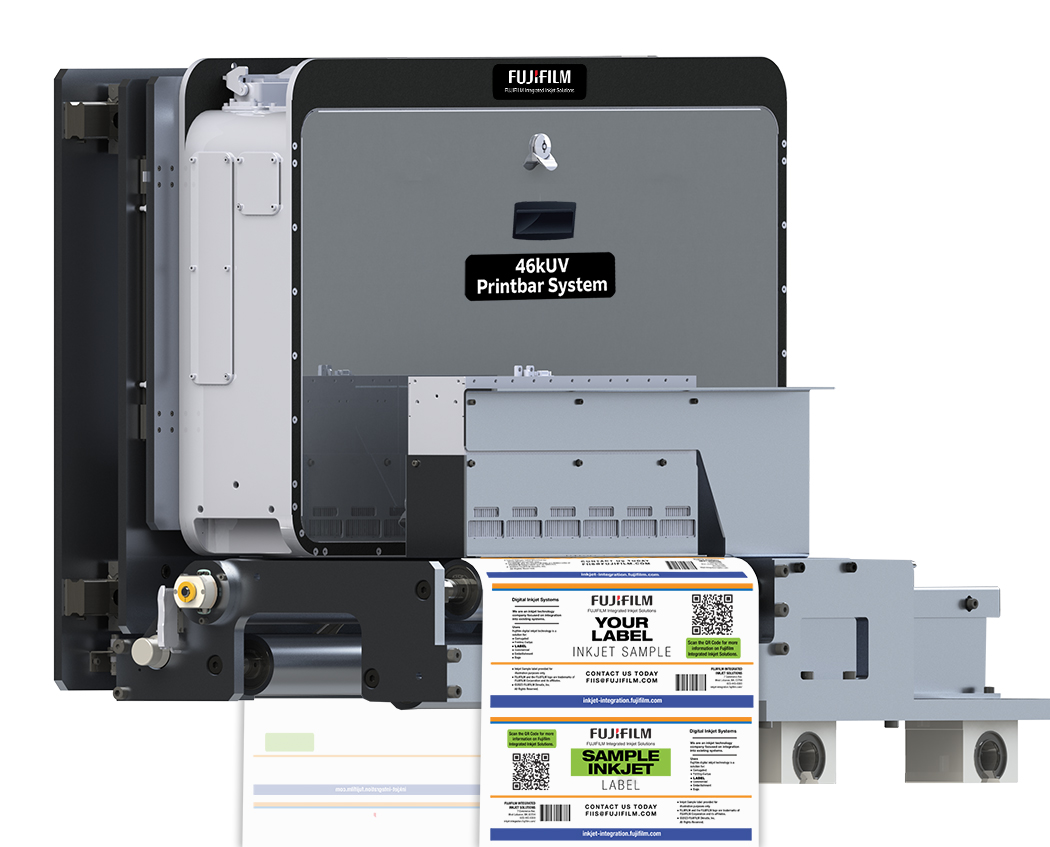

The Roll-to-roll Rewinder is a tabletop unit designed to support single pass inkjet technology.

- Size

1092.2 x 457.2 x 508 mm [43 x 18 x 20 in.]

- Weight

113.4 KG [250 lbs.]

- Max substrate roll diameter

304.8 mm [12 in.]

- Max substrate roll width

152.4 mm [6 in.]

- Substrate roll core diameter

76.2 mm [3 in.]

- Core locking

Manual

- Speed

10.7 – 152.4 meters per minute [35 – 500 feet per minute]

- Unit control

Manual through local HMI touch screen

- Auto tension control

Yes

- Tension control method

Pneumatic brake

- Substrate break detection

Yes

- End of substrate notification

Yes

- E-stop

Yes

- Encoder mounting bracket

Yes

- Mounting plate

M8 x 1.25 thread, 25.4 x 25.4 mm square pattern

- Substrate elevation

Even with top mounting plate

- Input power

230 VAC, Single phase, 50/60 Hz