These features are available in roll-to-roll, sheet-to-sheet, or roll-to-sheet. The FUJIFILM UNIGRAPHICA TransJet Transport’s scalable, modular configuration supports:

Supported options include:

The TransJet Transport is designed to work with finishing functions also available from Fujifilm Unigraphica, including:

Tension system

The FUJFILM UNIGRAPHICA TransJet Transport uses a network of movable, pneumatic tension rollers for simple, fast-starting, web control. Its vertically stacked duplex configuration enables precise printing with no turn bar, to minimized required floor space.

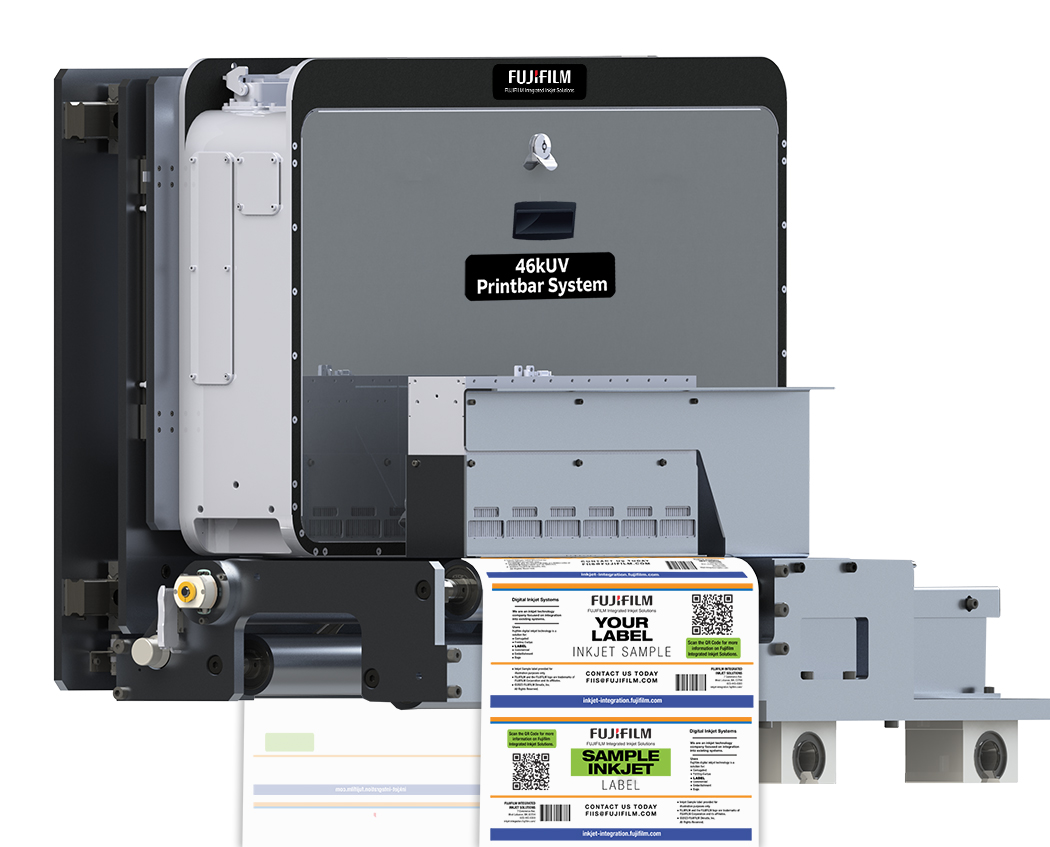

Works with Fujifilm’s high-quality printbar systems

Fujifilm’s highly engineered printbar systems include a wide variety of features to create the highest quality print system possible.

Features include numerous proprietary technologies, such as:

Time-of-Flight Compensation

Fujifilm’s advanced software system maintains registration within 0.0082 inches during substrate accelerations exceeding 16 ft/s2.

Automatic, real-time insetting

When imprinting on a pre-printed shell, Fujifilm’s automatic insetting maintains precise analog to digital alignment. It senses print position on the web by using fiducial marks and adjusts to movement automatically while printing.

It is precise to 0.1mm.

The vertically stacked duplex configuration efficiently uses floor space.

Fujifilm’s automatic, real-time insetting keeps imprinting within 0.1mm.

Although no print production operation will have perfect web splices every time, mitigating the effects of imperfect splicing helps maintain uninterrupted operations and provides sufficient design space for optimal add-on print systems. The combination of Fujifilm’s precise printhead technology and fast web repositioning enables high print quality on existing transports equipped with splicing processes.