This is a collection of examples of printed circuit boards (PCB).

Five example of Rubber roller mounting, Squeegee pressure distribution during cream solder printing, Dry film resist (DFR) lamination, Stacking or laminating machines for multilayer ceramic devices and Vacuum heat pressure devices are posted.

Table of contents

(1) Assessment of rubber roll mounting quality

Industry: Displays, printed boards, Lead frames, etc

Challenges: If the adhesion of the rubber to the steel core of the lamination nip roll is poor or if the rubber is damaged, lamination defects occur.

Benefits of Prescale: Time saving, Quality improvement

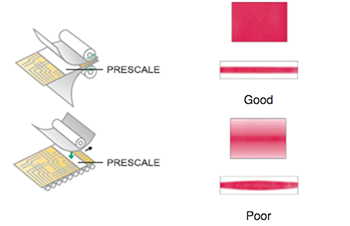

(2) Measurement of squeegee pressure distribution during cream solder printing

Industry: Printed Circuit Board (PCB) electronic component mounting

Challenges: When cream solder is screen printed onto print substrates, any nonuniformity in the squeegee pressure distribution will result in uneven application of the cream solder.

Benefits of Prescale: Time saving, Material savings, Quality improvement

(3) Checking adhesive pressure of dry film resist (DFR) lamination

Industry: Printed Circuit Board(PCB), Lead frames, Liquid crystal, etc

Challenges: Bubbles and wrinkes can be formed if the base material/dry film resist/lamination roll is not set up in balance or if the pressure is not adjusted to be uniform.

Benefits of Prescale: Time saving, Material savings

(4) Checking mold contact and pressure uniformity of stacking or laminating machines

Industry: Manufacture of laminated ceramics, Ceramic substrates and packages, PCBs, Electronic components for automobiles and mobile phones, Laminated devices

Challenges: Need to press in extremely high precision to avoid changes in electrical characteristics due to problems of poor adhesion or non-uniform thickness, and to avoid electrical connection failures due to displacement of the electrode pattern.

Benefits of Prescale: Yield improvement, Quality improvement, Accuracy improvement

(5) Verification of pressure uniformity of vacuum heat pressure devices

Industry: Electronic components, OLEDs, Touchscreens, Print circuit boards, Equipment such as semiconductors that are used as manufacturing and development machines

Challenges: The devices are expected or required to maintain as uniform surface pressure as long as possible to improve the quality of processed products.

Benefits of Prescale: Reduce of pressure failure or yield, Quality improvemnet